|

|

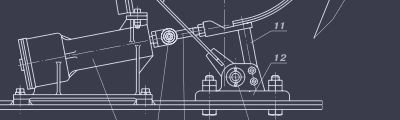

Drilling steel pipes

Drilling steel pipes have welded connections with cone thread, they are smoothbored, they have high strength and reliability, technological universalism and can be used for dimond and hard-alloy drilling. Also it can be used for non-core drilling by rock-bits, which includes drilling by bottom-hole hydropercussion and pneumatic hammers. Usage:

- In prospecting of solid commercial minerals and water for hole drilling of rotary core drilling and non-core drilling by hard-alloy and diamond bore bits, bits of all types, which includes drilling by bottom-hole hydropercussion and pneumatic hammers;

- In geotechnical investigations, in building. TBSU with welded tool joints performed instead of steel pipes with muft and joint tool connection (SBTM) and of steel pipes with pin connection (SBTN). TBSU includes advantage of the first (joint tool thread) and of the second (column plain outside) case.In underground extraction of seam of earth material for rotary drilling of degassing and technological holes (TBSU is an equivalent of tool string SBAB-42, drill bar ABG-300).

- In drilling and blasting operations;

- In oil and gas prospecting for geophysical research. They can be used for supplementary works in oil holes for cement plug drilling, for example, for hole washing. Pipes of diameter 43x4,5, 55x5,5, 63,5x6 can be used for hole thawing (working pressure of liquid during hole thawing can reach 700 kg/sm2), and also for cement injection and extraction of hydrate blocks.

There can be delivered card-weight pipes, card-weight pipes with cased-hardening, improved pipes with cased-hardening.

Technical characteristics

| Pipe diameter, mm |

Weight, kg with pipe length, mm: 1700/3200/4700/6200 |

Recommended range of hole diameters, mm |

| 63.5 |

15.1/25.3/35.0/44.8 |

76-132 |

|